Carbon ThreeSixty Launches Industry Leading Carbon Fibre Aftermarket Wheel

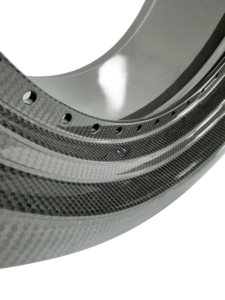

Chippenham, Wiltshire – Carbon ThreeSixty, a leading innovator in advanced materials and lightweighting solutions, has unveiled the latest product to be developed and manufactured at its new 44,000 sq ft factory in Wiltshire: a high-performance carbon fibre aftermarket wheel.

Carbon ThreeSixty has a long history of delivering carbon fibre barrels to the automotive market, and the latest aftermarket wheel announcement is testament to the company’s commitment to producing the highest quality products on the market.

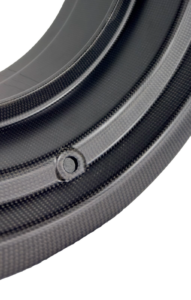

Available in sizes from 15” through to 23”, the carbon fibre barrels will fit almost any application – from the ever popular restomod through to the latest hypercar.

Carbon ThreeSixty hasn’t stopped there though; using the full catalogue of materials available on the market, clients can customise their barrels by specifying a classic plain weave carbon fibre, 2×2 twill or the signature forged carbon appearance. Couple this with a choice of finish, and clients can match their car’s aesthetics perfectly.

.

.

The Advantages of Carbon Fibre Wheels

Carbon fibre wheels offer numerous advantages over traditional alloy wheels:

- Reduced Unsprung Weight: Carbon fibre’s exceptional strength-to-weight ratio allows for a substantial reduction in unsprung weight. This translates to improved acceleration, braking, and overall responsiveness.

- Enhanced Handling and Performance: Less unsprung weight results in better tyre grip, reduced suspension workload, and improved steering feel. This translates to a more dynamic and engaging driving experience.

- Stunning Aesthetics: Carbon fibre’s unique visual appeal and customizable finishes add a touch of luxury and exclusivity to any vehicle.

Made in the UK

By combining advanced materials science with cutting-edge manufacturing techniques, Carbon ThreeSixty has created a truly exceptional product that redefines the standards of automotive wheel technology proudly produced in the UK.