Chippenham, UK; 12 January 2022. A significant barrier to the adoption of Fuel Cell powertrains, – storage of Hydrogen (H₂) fuel, could soon be overcome for Niche Vehicle builders after Carbon ThreeSixty Ltd won grant funding of £35k for a “rapid fire” feasibility study starting immediately.

Project CHiDES (Configurable Higher Density Energy Storage : Future Hydrogen Storage) won the funding after entering the latest single-company Feasibility Study round of the Niche Vehicle Network’s annual competition.

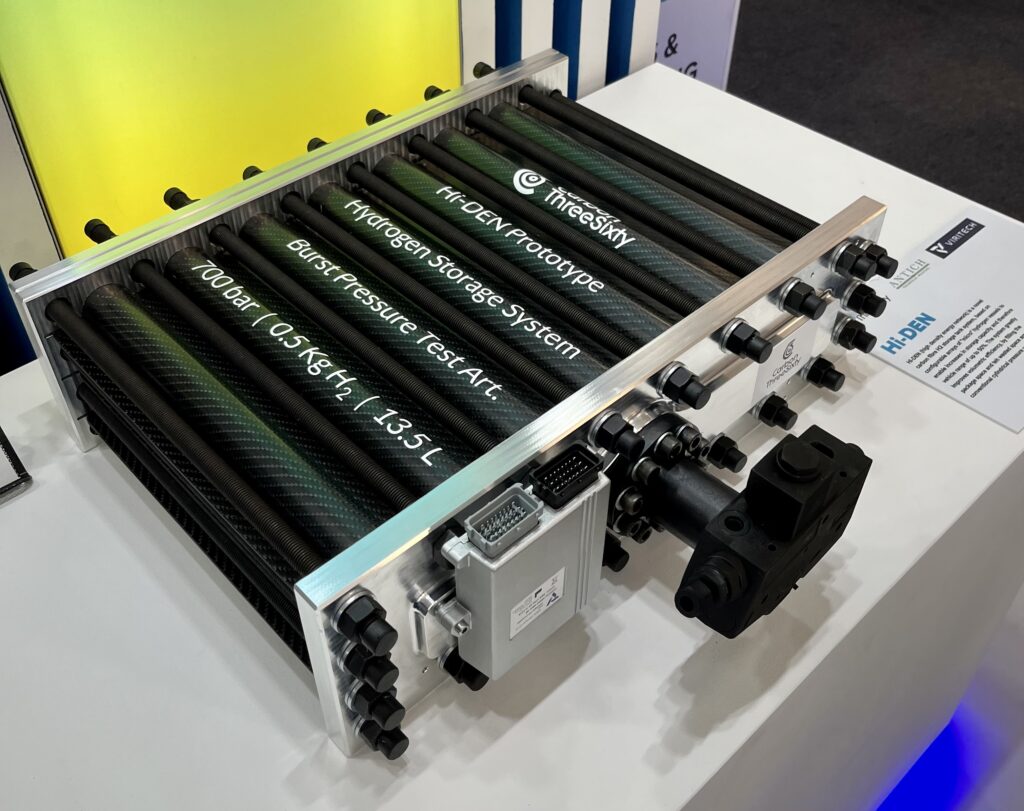

Optimised and robust Hydrogen storage systems are key enabling technology for the advancement of hydrogen and fuel cell technologies. CHiDES is a project conceived and managed by Carbon ThreeSixty Ltd to determine the feasibility of a revolutionary storage architecture for Hydrogen fuels. CTS will leverage its track record to explore the use of carbon fibre 3D woven fabrics to produce arrays of lined, reinforced pocketed structures, will enable configurable geometries and higher volumetric efficiency for Hydrogen storage. Current storage solutions are bulky large cylindrical vessels that significantly compromise vehicle design. CHiDES will lead to the offer of a completely new storage solution.

Ed Allnutt, Managing Director at Carbon ThreeSixty, which specialises in the design and manufacture of advanced composite structures, said:

“Carbon ThreeSixty has grown significantly in recent years, a significant proportion of this resulting from our on-going commitment to value-adding product R&D in high growth markets. The transition to clean fuel powertrains in niche automotive provides some unique challenges, and we’re delighted that we can begin work in earnest on a novel set of solutions to this problem”

Notes to editors

Carbon ThreeSixty provide light-weighting solutions through the use of advanced composite materials and manufacturing processes. They specialise in resin transfer moulding (RTM) processes and novel preforming techniques such as tailored fibre placement (TFP) to produce highly optimised and cost-effective structures. www.carbonthreesixty.com

The Niche Vehicle Network (NVN) is an independent association of niche vehicle manufacturers, specialist technology companies, system suppliers, research organisations, design and engineering companies, collaborating on the application of innovative technologies in specialist vehicle development and production. Through strategic funding, NVN aims to promote and stimulate R&D collaboration and partnership working to support the growth of UK niche vehicle manufacturers and their UK supply chains, safeguarding and creating jobs and skills. Backed by InnovateUK, the Office for Zero Emission Vehicles (OZEV), and the Advanced Propulsion Centre (APC), NVN provides funding to support collaborative research and strategic development activities in the adoption of low carbon vehicle technologies, including electric and hybrid propulsion, advanced battery systems, lightweight body and chassis structures, alternative propulsion systems and aerodynamics. The NVN programme plays a significant role in promoting the adoption of vehicle electrification and enabling technologies. www.nichevehiclenetwork.co.uk

Contacts

Carbon ThreeSixty

Ed Allnutt, Managing Director

info@carbonthreesixty.com

+44 1225 810005

Additional Coverage:

CompositesWorld – https://www.compositesworld.com/news/carbon-threesixty-wins-funding-to-explore-feasibility-of-novel-hydrogen-storage-architecture