Carbon ThreeSixty, the leading innovators in composite technologies and manufacturing, continues its investment in high end specialist software, complementing its already extensive suite of composite design and manufacturing tools.

The ability to accurately predict the behaviour of complex composites structures is a cornerstone capability of Carbon ThreeSixty. Through detailed simulation the Engineering team are able to rapidly develop new products and processes, enabling further growth of the company.

Altair Hyperworks is widely recognised as one of the leading software solutions for complex composite modelling. It allows CTS to work with numerous companies on the design, modelling and Finite Element Analysis (FEA) of products, ensuring that the structures we design are fully understood before manufacture and physical testing.The team are steadily building their ability to combine Hyperworks simulation with different manufacturing techniques, such as Tailored Fibre Placement (TFP) in conjunction with RTM and compression moulding. This ensures that CTS meets the exacting requirements of our clients.

CTS Lead Stress Engineer Goncalo Valente said “It is of key importance to have the state of the art tools that allow us to confidently study our composite structures in various fronts, always aiming for robustness, safety and lightweight. The full suite of Altair products enables CTS to go from concept design to detailed product development not only on the implicit level but also on complex dynamic problems with the Optistruct and Radioss solvers. The high demand in highly-optimised structures requires CTS to understand the product to the fibre tow level, linking Altair Hyperworks, EDOstructure and EDOPath and determining the tow path based on the stress tensors, exploring all the benefits of Tailored Fibre Placement”

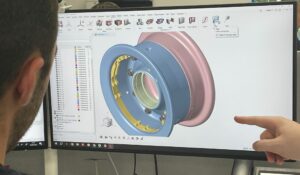

The addition of CATIA compliments the growing suite of CAD/CAM software utilised by Carbon ThreeSixty and brings additional functionality in designing complex shapes and surfaces utilised in both tooling and component design. Alan Purves (Technical Manager) leads the experienced engineering team in the use of CATIA at CTS.

In addition to these well known CAE packages, Carbon ThreeSixty has also invested in specialist software to aid in the capability development of its TFP manufacturing processes, namely EdoStructure and EdoPath. In combination these two packages enable the Engineering team to optimise fibre paths (position and orientation) to create lighter weight structures than can be achieved with pre-existing analysis.

If you have any projects that you would like to collaborate on with CTS that may use this extended software offering, please do not hesitate to get in touch at info@carbonthreesixty.com

The further investment demonstrates Carbon ThreeSixty’s ongoing success and commitment to re-investing in additional manufacturing capability and growth.

beep-bop-bzzzrrrr-beep-bop…Robot out.

Notes to Editors

Carbon ThreeSixty is a turnkey provider for the design, development and manufacture of highly challenging, advanced composite structures. We are a valued partner in the delivery of innovation, engineering and manufacturing services to the Aerospace, Automotive, Energy and Defence sectors. We specialise in resin transfer moulding (RTM) processes and novel preforming techniques such as tailored fibre placement (TFP) to produce highly optimised and cost-effective structures. https://carbonthreesixty.com