Chippenham, UK; 13 Jul 2020. Carbon ThreeSixty, the advanced composites structure specialists, are delighted to announce a recent software investment that further enhances their existing generative design and FE analysis capabilities.

In collaboration with their preferred software vendor SolidSolutions Ltd, Carbon ThreeSixty have elected to bring in a full suite of Solidworks Simulation Premium tools to complement their existing seats of Solidworks CAD.

Will Battrick, Chief Technologist at Carbon ThreeSixty, said:

“As Carbon ThreeSixty continues its expansion into ever more challenging new markets, it is critical that we deliver to our clients well understood and highly optimised products, all the while preserving our reputation for swift, agile service.”

“Validated digital twin modelling of composite materials, along with topological and laminate optimisation, are non-trivial challenges that require expertise in a number of disciplines – micro-mechanics, materials, FE results interpretation, alongside the capability to actually manufacture those designs.

“Providing our team with the right tools to excel has always been a key part of our growth strategy, so I’m delighted to bring this capability in-house.”

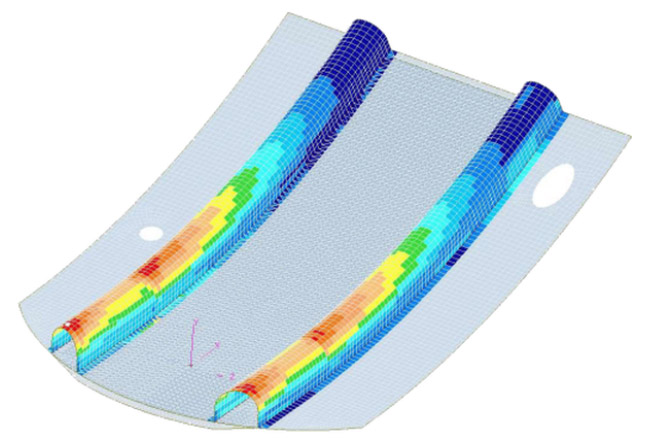

Solidworks Simulation Premium adds capability in complex loading scenarios including non-linear and dynamic / impact events, as well as modal, buckling and thermal analysis. Crucially this also allows Carbon ThreeSixty to model ply level composite behaviour and perform design and topology optimisation analysis to enable further optimisation and mass reduction of their already lightweight composite structures.

The extended software capability will immediately impact several current commercial and R&D projects and allow faster, better, lighter, stronger, cheaper structures to be developed. In particular the optimisation elements dovetail well with Carbon ThreeSixty’s Tailored Fibre Placement (TFP) and additive 3D printing technology, which will help guide the placement of fibres with this freeform, localised reinforcement capability.

The extended software capability will immediately impact several current commercial and R&D projects and allow faster, better, lighter, stronger, cheaper structures to be developed. In particular the optimisation elements dovetail well with Carbon ThreeSixty’s Tailored Fibre Placement (TFP) and additive 3D printing technology, which will help guide the placement of fibres with this freeform, localised reinforcement capability.

Notes to Editors:

Carbon ThreeSixty provide lightweighting solutions through the use of advanced composite materials and manufacturing processes. They specialise in resin transfer moulding (RTM) processes and novel preforming techniques such as tailored fibre placement (TFP) to produce highly optimised and cost-effective structures. www.carbonthreesixty.com