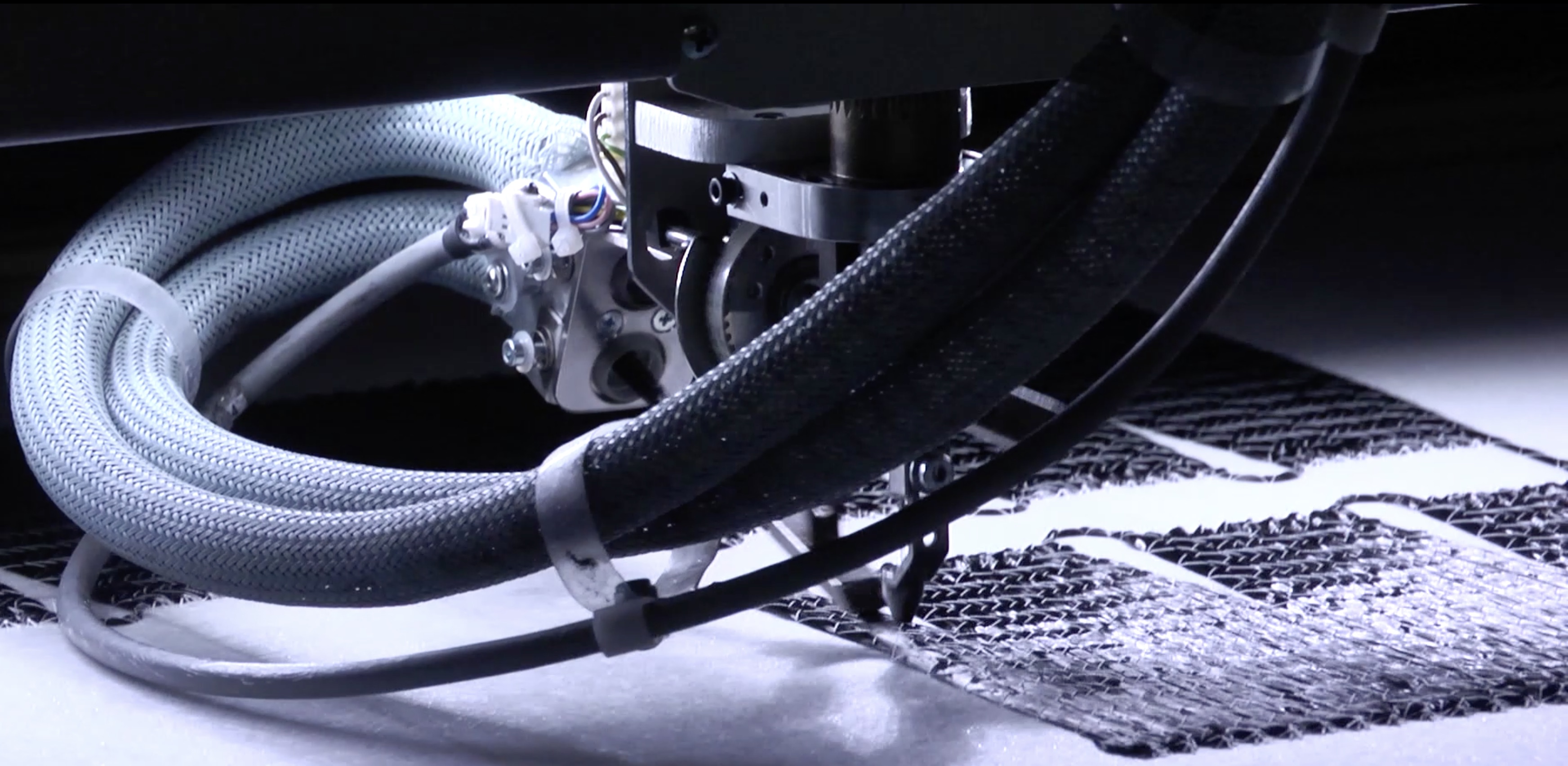

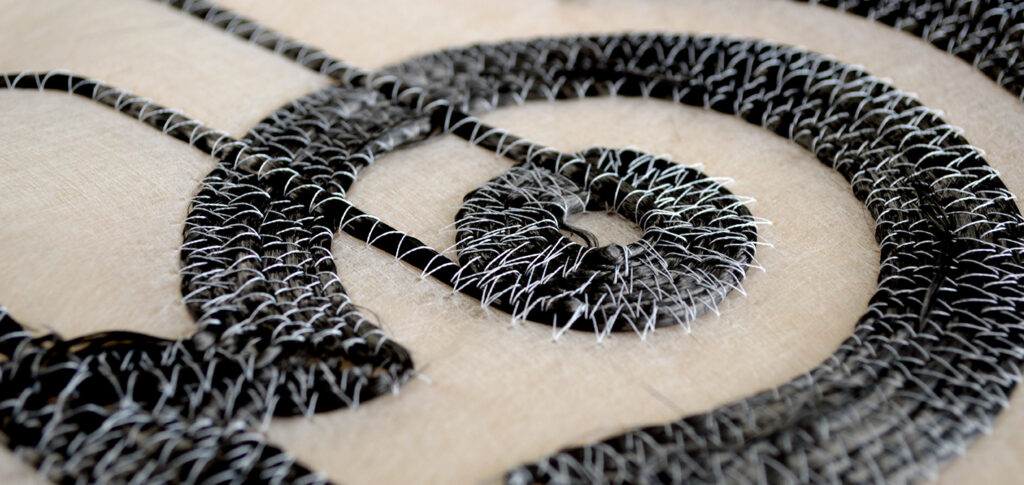

Tailored Fibre Placement (TFP) is an innovative, automated method of manufacturing highly optimised fibre preforms. Based on technology deployed for decades in embroidery it is a highly scalable and repeatable “lights out” process. The process enables fibres to be accurately laid down at precise angles and exact positions. By optimising fibre angle and positions, the vast majority of source material is productively used, virtually eliminating waste.

Carbon ThreeSixty’s in-house Tailored Fibre Placement preforms are used in our existing products, enabling unrivalled optimisation in both strength and stiffness. Complex 3D products are made possible by using netting techniques to drape and form from 2D to 3D.

Having this capability enables Carbon ThreeSixty to design and build our own product specific preforms and fabrics on site in a matter of minutes.

Utilising automated processes also enables the scale up of future, high volume production.