Resin Transfer Moulding is a composite manufacturing process in which a preform made of fibre reinforcement is placed in a closed mould cavity, a vacuum is applied and then resin is injected under pressure. The resin cures and hardens, resulting in a composite part with complex geometric features and high strength-to-weight ratio.

RTM is a versatile process that can be used to produce a wide variety of composite parts. It is a relatively low-cost process that can be highly automated, making it well-suited for volume production.

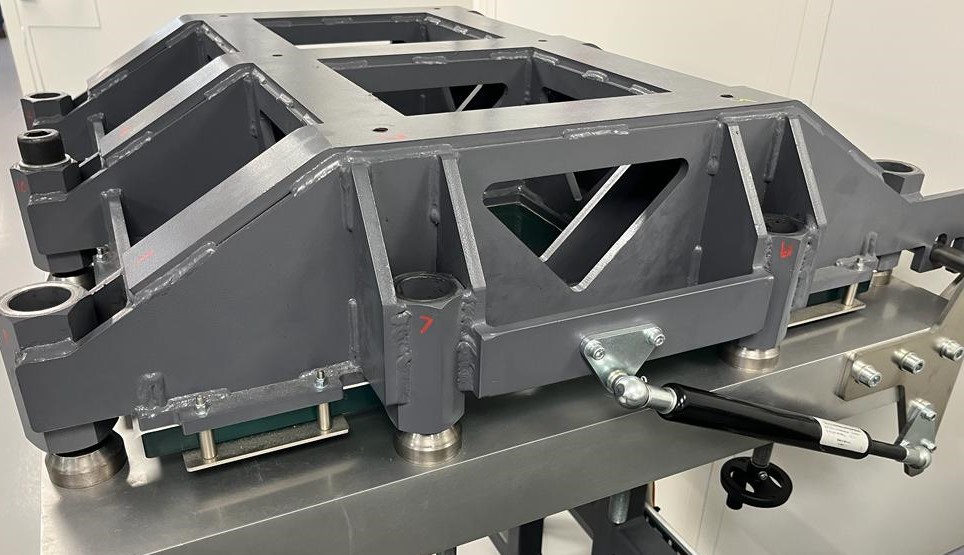

Carbon ThreeSixty has decades of experience designing highly complex moulds and has developed an industry leading understanding of the fundamental principles of RTM. We are highly skilled in the design and manufacture of tooling and components for the production of high quality complex composite structures to a tight tolerance.