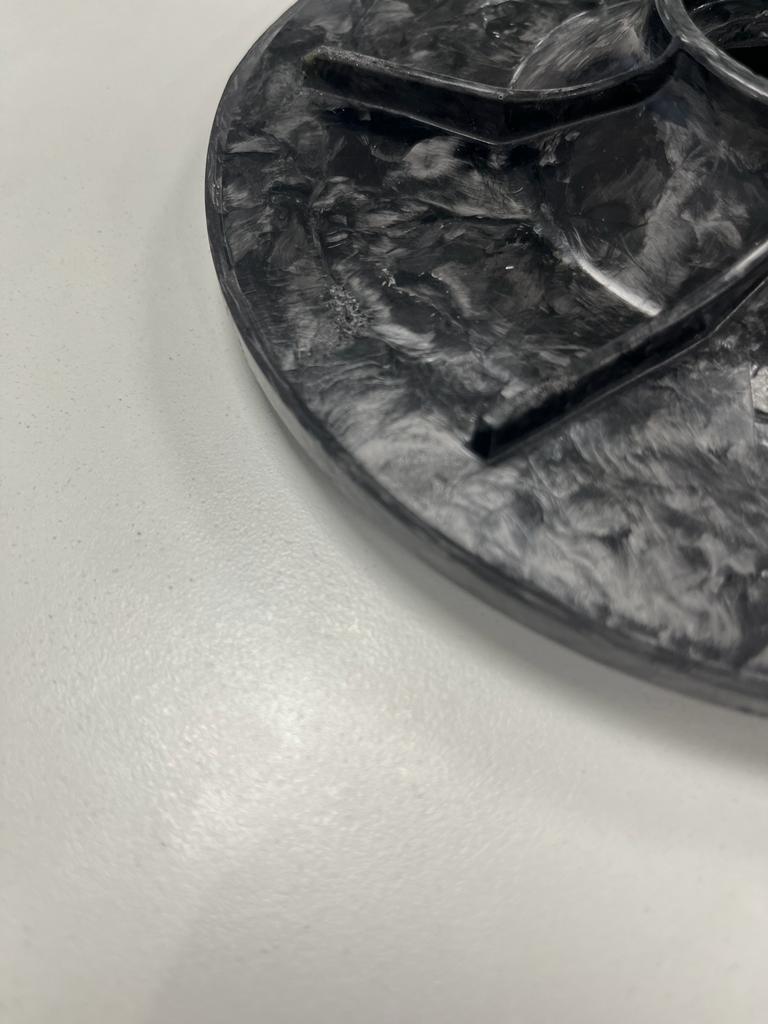

Carbon ThreeSixty’s Compression Moulding capability can be used to manufacture thermoset and/or thermoplastic composites. Unlike RTM the resin/matrix is already part of the preform rather than injected afterwards. The matrix could be in the form of a pre-impregnated resin such as in Sheet Moulding Compound (SMC) or through the use of “co-mingled” fibres. We also have experience in wet pressing, a process where liquid resin is dosed onto the preform before the mould tools are closed.

Preforms are compressed in their moulds using precision PLC controlled presses. These presses apply heat in addition to a substantial compressive load. This process ensures that the parts are manufactured to near net shape reducing excess waste of materials. Used in conjunction with our other cutting edge manufacturing techniques such as Tailored fibre placement (TFP) allows us to design and manufacture highly complex structures. We have 2 presses in our facility see capabilities listing(Link) dedicated to the manufacture of compression moulded components.