This goes from the drawing board to rolling off the production line in volume, from design to manufacture.

We don’t separate design from manufacture – our philosophy is that each is a component of the other; it is pointless to have a fantastic design if it can’t be profitably manufactured; and manufacturing a product which lacks design elegance will severely limit sales.

While relentlessly focussing on function and performance, we are also acutely aware of the importance of the sustainability of our work. We prioritise bio-resin, recycled and recyclable material wherever possible. Our business model is based on sustainability – in fact there would be no Carbon ThreeSixty if we could not deliver a step change improvement in environmental performance of our customers.

Materials

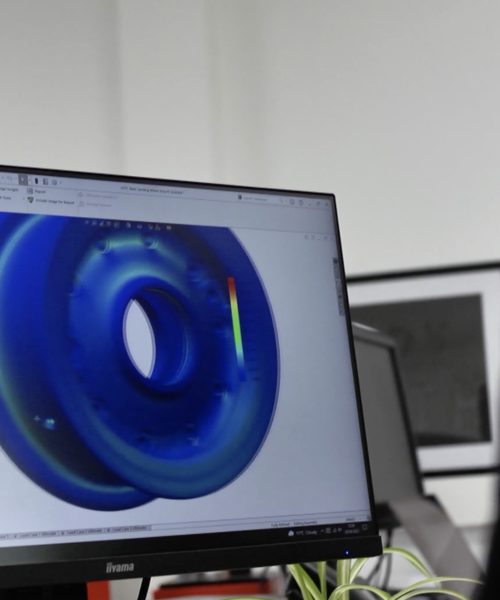

Design & Analysis

Tooling

Manufacturing Process

Quality Assurance

The team have extensive skills in material science, working a large range of materials in various formats; carbon, glass, thermoplastic and natural fibre, from braids, wovens, non-wovens, heavy fabrics – in fact any material you want to include in a composite, we have the kit and the team to make it a reality.

Similarly with resins, the wide range of knowledge and experiences of the Carbon ThreeSixty team enables us to select the most appropriate resin that will best achieve the required characteristics whilst being mindful of sustainability, whether that’s very advanced multi-functional systems, high temperature cyanate ester matrices, bio-derived resins, or proven technology that still has benefits under certain conditions but requires specific knowledge and skills for effective application. To enable analysis we have a NETZSCH DSC 300 Caliris DSC high performance thermal analysis machine.

And of course it covers thermoplastic vs thermoset. We are agnostic – we chose the right format for the right use; we are as comfortable with each and are part of the transition to tough thermoplastic matrices providing a viable route to sustainability and recycling.

Quality - At the end of the process, after all the design and manufacturing, we assure the quality with modern equipment, any that you would expect in a QA lab. This includes Coordinate Measuring Machines (CMMs), dynamic mechanical analysis, differential scanning calorimetry. Our engineering specialists conduct detailed inspection with full product traceability by RFID tags. They undertake rigorous product testing to recognised international standards, covering impact and fatigue testing.

At Carbon ThreeSixty we enable design flexibility by selecting from a wider range of fibres and resins often in their lowest cost formats which few other companies can work with, and deliver what the industry needs.

Combining our knowledge, experience and skills with the latest technology means the process of scaling up to full production is a seamless transition for clients. Below are just a few of the key competences we harness to drive innovation in composites.

This is setting the foundations for the next stage of wider composite exploitation, with wider adoption and broader usage of composite products in more industries.

Carbon ThreeSixty’s production engineers can pull together whole processes for whole assemblies. There is another huge value-add to our clients centred on our experience and skills in on out-of-autoclave (OOA) processes. OOA has been described as the green solution for composites manufacture. It reduces energy consumption, decreases cycle times and cuts both capital and tooling expenditure.

It is also a huge benefit to the industry, enabling more innovative and smaller composites companies – like Carbon ThreeSixty – to stake a place in the market and disrupt existing processes.

This is setting the foundations for the next stage of wider composite exploitation, with broader usage in more industries. At Carbon ThreeSixty we enable design flexibility by selecting from a wider range of fibres and resins often in their lowest cost formats which few other companies can work with, and deliver what the industry needs.

Combining our knowledge, experience and skills with the latest technology means the process of scaling up to full production has few surprises and any creases are easily ironed out. Below are just a few of the key competences we harness to drive innovation in composites.

PREFORMING & TAILORED FIBRE PLACEMENT (TFP)

TFP is an innovative, automated method of manufacturing highly optimised dry fibre preforms. It has been proven in aligned industries with highly scalable machine architecture. The process enables fibres to be accurately laid down at precise angles time and time again. By optimising fibre angle and positions, the vast majority of source material is productively used, virtually eliminating waste.

Carbon ThreeSixty’s inhouse TFP preforms are used in our existing products, enabling unrivalled optimisation in both strength and stiffness. Complex 3D products are made possible by using netting techniques to drape and form from 2D to 3D.

Having this in-house capability enables Carbon ThreeSixty to design and build our own product specific preforms and fabrics on site in a matter of minutes.

Utilising automated processes also enables the scale up of future, high volume production.

We can also deploy filament winding to manufacture cylinders or pressure vessels or tanks

VACUUM PRESSURE INFUSION

Vacuum Pressure Infusion (VPI) drives resin into a laminate quickly and efficiently, ensuring there is no gapping or areas of the composite layers which will not cure. This is really important especially for electronics applications, for example.

The materials are laid dry into the mould and inserted into a bag. After the vacuum is applied, the resin is introduced, being sucked into the laminate and throughout the structure.

This improves the fibre-to-resin ratio and results in a stronger and lighter product. Benefits include less waste, consistency of resin application and it is cleaner and safer. It also ensures the minimum amount of resin is applied, which has an impact on toughness and weight.

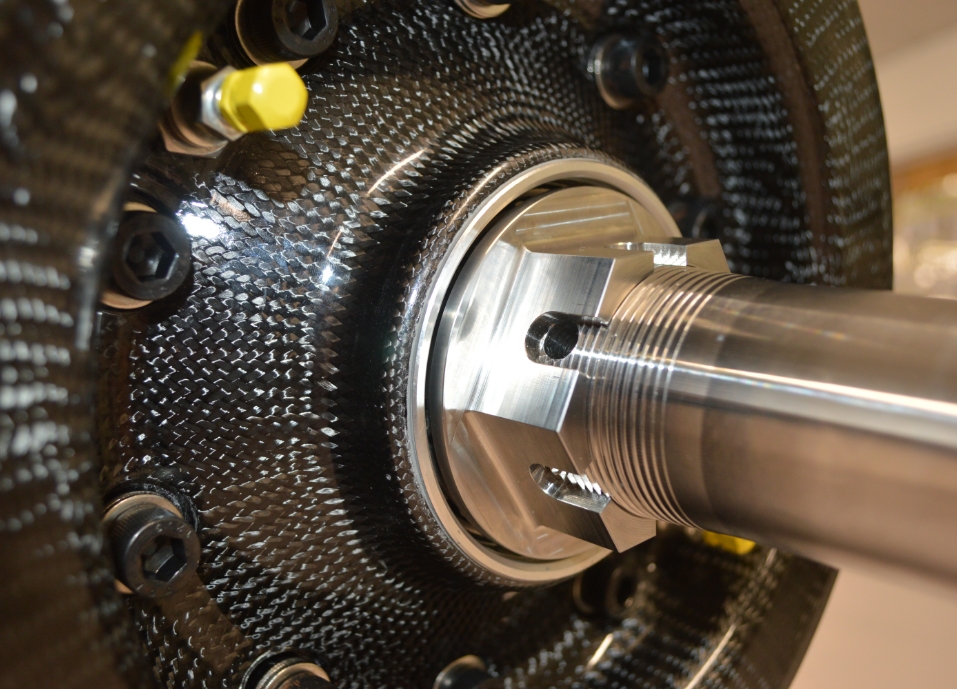

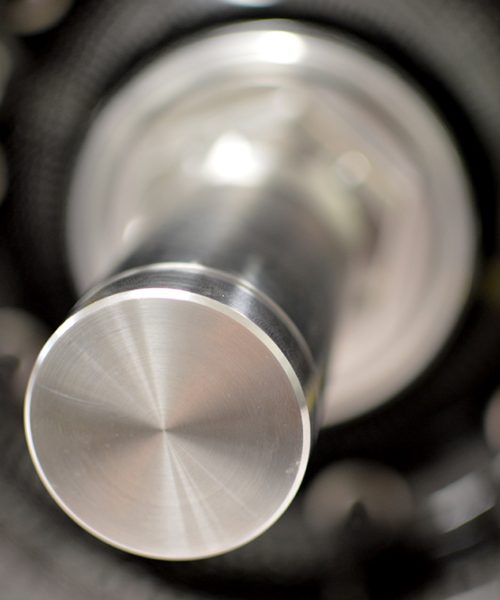

RESIN TRANSFER MOULDING (RTM)

The Carbon ThreeSixty team are experts in RTM and similar infusion-based manufacturing techniques. The benefits of RTM include the ability to produce lightweight and extremely durable parts with complex geometries and excellent surface finish all round, making in effect two A-surfaces, unlike traditional pre-preg moulding. Additional freedom to select specific reinforcement materials, and their hybrids, along-side novel or bespoke resin matrix systems allow the production of highly functional products.

RTM has great flexibility, which enables us to tailor the materials and resins to the specified strength and to fabricate geometries and shapes which are difficult using other processes. And there is much less waste and higher production volumes are achievable than autoclave competing processes.

Working in close collaboration with suppliers, the team fully understands the technical specifications and capabilities of both machines and materials. This enables ongoing development of proprietary manufacturing processes to harness the full potential of carbon composites, and continually improve product performance. Carbon ThreeSixty products are primarily manufactured via resin transfer moulding. This reduces production costs as there is less resin wasted and enhanced repeatability. We achieve consistency in manufacture with this more environmentally friendly process. This is especially important for working conditions for our engineers.

We also use compression moulding when this is the most suitable technique.

OVENS, CLEAN ROOM & MACHINING

Carbon ThreeSixty’s engineers make extensive use of our fully calibrated and data-logged ovens. These can operate up to 300oC and are programmable with controlled ramp rates. They are available for running 24/7 and over weekends, for those organisations seeking a particularly quick turn-around. The ovens measure up to 2m x2m x 2m.

Our clean room is environmentally controlled, delivering repeatability and robustness.

And we can also subtractive machine our own products and tools. Our approach at Carbon ThreeSixty is to develop capability in-house where there are bottle-necks in the market or a very complex or specialist machining operation is required.

A process to use continuous filaments of fibre to produce cylindrical or spherical structures. The manufacturing process allows for a wide variety of fibre angles to create maximum strength and stiffness to withstand high loads and stress. A wide variety of combinations of fibre and matrix materials provide a fully flexible and tailored manufacturing process. Our robotic 7 axis filament winder is are capable of producing a variety of structures with

Compression moulding is used to create thermoset and thermoplastic matrices composites through the use of heat and pressure. This process ensures that the parts are manufactured to near net shape reducing excess waste of materials. Used in conjunction with our other cutting edge manufacturing techniques such as Tailored fibre placement (TFP) allows us to design and manufacture highly complex structures. We have 2 presses in our facility see capabilities listing(Link) dedicated to the manufacture of compression moulded components.

Carbon ThreeSixty’s in-house TFP preforms are used in our existing products, enabling unrivalled optimisation in both strength and stiffness. Complex 3D products are made possible by using netting techniques to drape and form from 2D to 3D. Having this capability enables Carbon ThreeSixty to design and build our own product specific preforms and fabrics on site in a matter of minutes.

Utilising automated processes also enables the scale up of future, high volume production.

CONTENT TO BE ADDED

We are committed to expanding our capital equipment continuously to stay ahead of the curve in composite manufacturing technology. Current capabilities include 7 axis robotic filament winder, X-winder, 400 tonne Langzauner press, 100 tonne high temperature (400C) press,, Tailored fibre placement machine, RTM Injection machines, HAAS CNC, 2 x CMM, curing ovens, (refine) .

Will Battrick MEng

CHIEF TECHNOLOGIST, CO-FOUNDER